blog

Automation in Warehousing: The Key to Efficiency and Productivity

By Mohan S AI and ML February 27, 2023

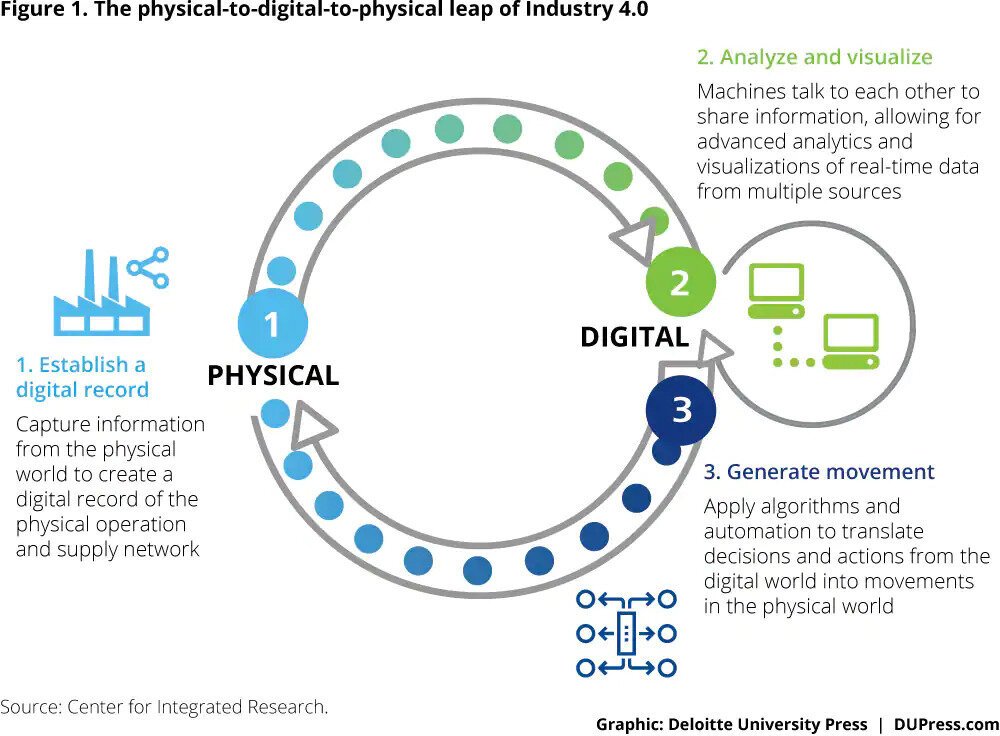

Digital transformation has elevated the productivity of many warehouses. It augments manual work and allows workers to shift from doing tedious work to focus on tasks with more complexities. Warehouse automation is changing the way warehouses operate. From automating the inventory to tracking the products from arrival to delivery, warehouses leveraged with automation, work with accuracy and improved safety, while reducing the overall cost.

Process Automation

Process automation is when software technology is used towards setting business goals of an organization by using automation in its processes and functions. Process automation is used in producing products, hiring employees and providing customer care services.

Walmart recently announced the acquisition of Alert innovation, a robotics automation company that develops technology which automates order fulfillment in the supply chain. Fully automated warehouses are equipped with softwares to help coordinate the process and operations of transportation of equipment in a warehouse. WPS - warehouse management system is the software that directs which product goes where and what are the operations to be performed. WPS interacts with WCS - warehouse control system which works on coordinating the movement of the machine.

These two technologies alone allow all movements in a warehouse to be fully automated, resulting in an optimized and an error free process.

Physical Automation

Physical automation is a process where technology is used to minimize the movement of employees, so the workflow can become more efficient. Physical automation is ideal for large scale warehouses where robots can process physical automation.

AGV’s - Automated guided vehicles are known to be one of the first physical automation technologies automating internal logistics. Now technologies like AS/RS - Automated Storage and Retrieval Systems and AMRs - Automated Mobile Robots have improved cycle time, inventory efficiency and overall productivity of many warehouses.

Amware fulfillment studies show that travel time accounts for up to half of total picking time in warehouses. Physical automation can reduce this time consumption, substantially. The main advantages of physical automation include:

Increased warehouse capacity

Better efficiency

Enhanced reliability

Scalability of services

Improved performance

Smart Warehouse Apps

Mobile technology has completely transformed warehouse processes. Warehouse management apps for mobile devices are being developed to further ease the warehouse management process. These apps can catalog and organize items by name, date and quantity. There are barcode scanners in these apps that enable warehouse managers to use internal codes.

Warehouse managers make use of mobile apps to connect to their WMS systems and track inventory and create reports to monitor warehouse productivity.

Benefits of using warehouse management apps are:

Enhanced business intelligence

Real-time reporting

Better sales

Improved efficiency

Higher productivity

Cost-savings

Considerations for Implementing Automation in Warehousing

Adapting to complete automation can not be done overnight and without thought. Planning the transformation of your warehouse from manual to automated, requires an organization to properly chalk out a plan based on many factors. Evaluating your process and procedures, examining your supply chain, getting an in house expert and striking a balance between your business goals and the needed technology.

Some of the questions you need to ask before implementing automation in your warehouse are:

Are you experiencing delays in order deliveries?

Are your existing warehouse processes and procedures labor-intensive?

Are you efficiently fulfilling order capacity?

Is your involuntary account accurate?

Are legacy systems present in your processes?

Are you customers satisfied?

Answers to these questions can greatly help in deciding, which field of your warehouse functions need automation urgently and most direly.

Factors to consider before automating your warehouse are:

Overall cost

Calculate the ROI and flexibility

Preparing your employees

robot/technology management

Future Trends in Automation for Warehousing

Technology is constantly evolving and advancements are being made on the go. The latest trends in warehouse automation includes the use of cloud based WMS systems, artificial intelligence and IoT.

Cloud based WMS - Cloud based warehouse management solutions rid companies from needing software or hardware to manage WMS on the site. Rescuing the burden on the IT team. Cloud based WMS has following benefits:

Centralized information sharing

Cost reduction

Controlled Inventory Management

Easier integration of other systems

IoT - IoT allows seamless communication between multiple facilities for successful automation. It connects all the devices in the system, creating an ecosystem of devices to improve efficiency of the workflow. IoT makes sure systems like AGVs and AMRs, ERPs and WMSs and all the manual workers stay connected on the same page, in real time.

AI - Some of the artificial intelligence technology being used in warehouse functions includes wearables. Language processing and voice picking technology enables workers to operate hands free and safely. Smart glasses automatically scan barcodes.

Conclusion

Automation in warehouse operations has advantages that include higher production rate, increase in efficiency, better productivity, less material waste, enhanced product quality, improved safety, shorter work weeks for employees and reduced costs. There is no question that these benefits outweigh any apprehensions upon the need for automation in warehouse functions.

Automation can positively impact your warehouse systems and your business, in the long run. Companies that adapt quickly to the advanced technology will use it as a competitive advantage. Advance automation is not just a tool to reduce cost or increase productivity, it is a means of survival.