blog

6 Ways Construction Industry Is Transforming in 2023

By Mohan S Digital transformation December 8, 2022

Innovation and digital transformation is how the construction industry is aiming to achieve excellence in the year of 2023. Winning project bids isn't easy, that is why understanding your main issues and resolving them with a coherent approach by using technology creates a faster, more concise approach to achieve construction goals.

6 Trends Transforming the construction Industry

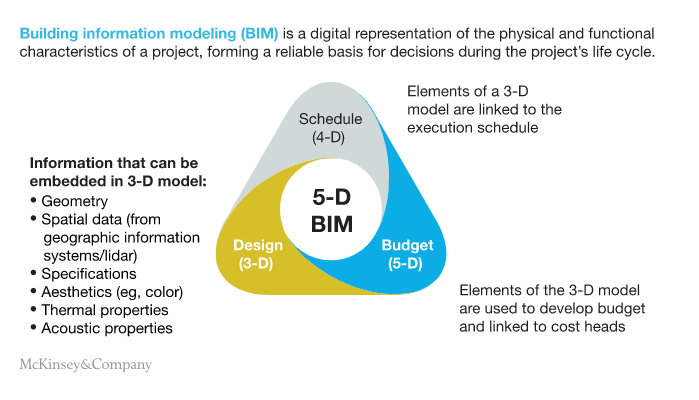

Building Information Modeling (BIM)

BIM or Building Information Modelling is a digital representation of the architectural and engineering model of a project. It is usually a 3-D prototype to showcase all details about the construction project. It helps designers, architects and contractors to develop a plan to build and design smoothly. It is a shared access design amongst many parties involved in the process of building. This makes collaborating a much easier task.

BIM is useful for:

Saving cost and resources -

BIM helps in predicting how much and what kind of material will be used in construction. This saves developers from making any errors and losing cost.

Centralized sharing

BIM saves all project related information on one platform. This shared access not only allows every expert on the project to have access to the data but it also keeps data safe in real time.

Adaptable technology

BIM can be adapted to other technologies like robotics and 3-D printing which means the efficiency of the construction can be increased.

Benefits of BIM

(Source: https://www.mckinsey.com/capabilities/operations/our-insights/imagining-constructions-digital-future)

1. Real-Time Data Sharing, Integration, and Coordination Across Stakeholders

Sharing the accurate information at the right time across all people involved in the project can be a tidal and time consuming task. It consumes great time while leaving all parties hanging. Real time data sharing allows exchanging data and information swiftly within time. Enabling the whole crew to work quicker and systematically.

2. Data-Driven Construction Planning and Lean Execution

For the optimization of the resources, builders can rely on technologies like big data to learn from the history of construction projects. Technologies such as RFID tracking can help identify tagged construction material and tools. Decreasing the chances of theft or material wastage.

3. New Fabrication Methods.

The detailed information provided by BIM can help initiate a faster and precise process towards building. Here accurate prediction of material quantity, weather predictions to align construction timing, safer environment to work in and easier operations of construction can be achieved.

4. Automated and Autonomous Construction

Advanced automation can help manage machines like bulldozers, cranes, trucks and excavators by using robots and technology. Most risk involved tasks handling heavy machinery can be achieved through automation.

5. Construction Monitoring and Surveillance

Drones for surveillance, laser scanning to compare the construction to the AI model or fuel and material consumption being detected by telematics systems, BIM contributes towards reducing the corrective process as well.

Advanced monitoring and inspection techniques

Imagine every piece of equipment being able to talk. IoT enables this conversation between tools, machinery and other equipment to reach a stabilized center device or an application, where all the information provided by these tools help accelerate the process of a construction project while keeping things organized.

Timely maintenance reminders, advanced equipment communication and automated alerts by compiling data through IoT can help increase equipment life.

Connected devices can alert when stock is about to run out so that time management of refilling the stock can happen.

Smart sensors that send vibrations through a struction and hence detect any deformities in it, which can be rectified in time.

On site efficiency can be achieved by sensors that monitor fuel consumption, helping in cost reduction and lowering carbon footprint.

Wearable technology can send signals if crew or vehicles are not in operation for a certain amount of time. This helps tracking inefficiency while increasing safety of the crew.

Construction Worker Safety

Construction sites are filled with dangers and risks of accidents due to the hazardous nature of the work. Important to mention that the cost of construction workers insurance is also a big matter to tackle. This is when the construction industry is turning to smart wearables. Increasing on site crew safety has become possible through smart gear.

Smart headgear

Hard hats have been used for decades to save construction workers from head injuries. But the new smart headgear has a 360 degree camera to scan and predict where the most chances of incidents are, which can help the worker be more careful around such spaces.

Smart caps measure brain waves to track decreased activity in a worker. This can alert the crew if a worker is overworked or fatigued and about to fall asleep. Increasing the chances of the crew being safer from any accidents.

Smart watches

Smart watches detect the overall health of a worker. From heart rate to oxygen levels. In case of any signs of risk, these watches can alert the close ones of its wearer.

Smart Vests

The new smart vests come with built in ice packs and coolers to keep workers cold during the hot summer months, reducing risks of heat strokes. While in winter the same vests can have a heating system to help these workers stay warm and save them from working in extreme weather conditions.

These vests are also equipped to detect any hazardous gasses and spaces so the wearer is alerted if they are in an area where they can be exposed to toxic contents.

Clip on devices

Clip ons are extremely useful. A worker can pick a clip on device and wear it while entering work. These devices are individually worn so they not only help maintain an attendance but also alert each crew member in the time of an emergency because an automated alert can be sent on them. They are extremely useful in alarming other crew members if one worker meets an accident and needs to send an emergency help signal.

Green Buildings

Construction is one of the biggest industries causing environmental pollution throughout the world. Reducing the carbon footprint left behind this industry is a huge concern. Companies are increasingly going green in their efforts to reduce pollution caused by their projects. This impact is mainly reduced by using technology to improve operations. Green buildings are also a huge contribution towards creating sustainability because they are environmentally responsible and resource efficient.

Connected Construction Site

A connected work site can mean increased productivity through shared data amongst managers, workers and officers. By sharing information through a centralized platform, everyone can keep ahead on the design changes, remodeling or any progress being made on the project. Real time sharing of this information can reduce the length of a project, saving millions in return.

AI commits less errors than humans. A digitally connected construction site ensures manual errors are not committed. A measurement taken manually can be inaccurate compared to doing it digitally. Collecting data manually on paper also takes more time while the written data is susceptible to loss or damage. Whereas, a digitally connected site can not only take accurate data but keep it safe while doing it faster.

Conclusion

The Construction Industry being one of the biggest industries in the world has to be the most responsible as well. Businesses around the world realize how big of a contributor technology and digitization is in achieving productivity. Smart gear, BIM, connected sites and advanced monitoring are not restricted to benefit the optimization and amplification of construction, they are also a vital necessity for the earth.